Creating a Self-Assembling, Iridescent Architectural Facade

Title

A Needle Woman: Galaxy was a Memory, Earth is a Souvenir

Project Duration

6 months

Team

Kimsooja, Prof. Dr. Ulrich Wiesner, Stephanie Owens, Jaeho Chong, Dr. Hiroaki Sai

Role

Material Design & Project Coordination

Featured in

ART21 | PBS FRIEZE SPACE designboom

A Needle Woman: Galaxy was a Memory, Earth is a Souvenir

Project Duration

6 months

Team

Kimsooja, Prof. Dr. Ulrich Wiesner, Stephanie Owens, Jaeho Chong, Dr. Hiroaki Sai

Role

Material Design & Project Coordination

Featured in

ART21 | PBS FRIEZE SPACE designboom

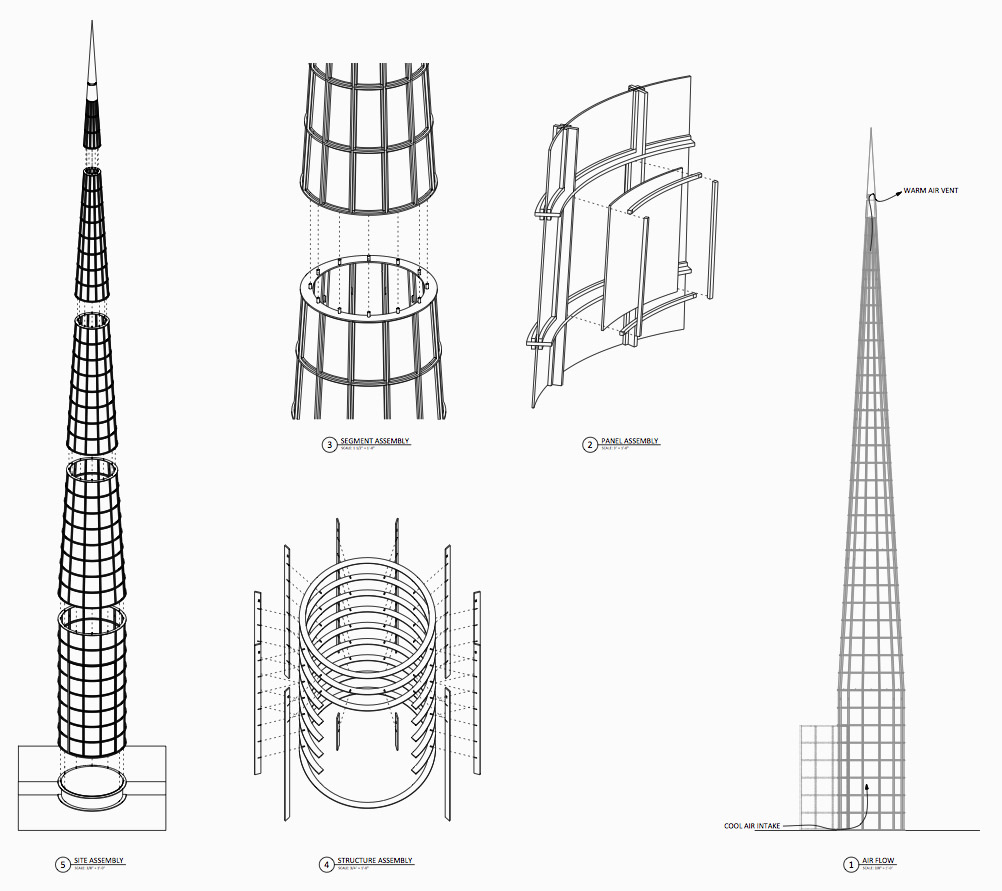

A Needle Woman: Galaxy was a Memory, Earth is a Souvenir is a 14-meter-tall needle-like pavilion with a bottom diameter of 1.4 meter and iridescent appearance. Its entire façade is covered in a self-assembled nanostructure that is made from a novel and custom-made material (see photo above).

The pavilion (see photo below) was created in collaboration with the Kimsooja Studio and the Wiesner Materials Science Lab. It was first erected as part of the 2014 Cornell Council for the Arts Biennial Intimate Cosmologies: The Aesthetics of Scale in an Age of Nanotechnology, Cornell University, New York, and exhibited at Frieze Sculpture 2018, London.

The pavilion (see photo below) was created in collaboration with the Kimsooja Studio and the Wiesner Materials Science Lab. It was first erected as part of the 2014 Cornell Council for the Arts Biennial Intimate Cosmologies: The Aesthetics of Scale in an Age of Nanotechnology, Cornell University, New York, and exhibited at Frieze Sculpture 2018, London.

CONTEXT

Much of what determines our lives, naturally and technologically, lies beyond our immediate sensory perception. Both the arts and the sciences are our attempts to understand and describe the world around us. In this collaborative project, art practise and scientific research come together to mutually explore the process of creation, to learn from and reflect on each other, to unite the audiences, and to find the novel together.

There’s Plenty of Room at the Bottom, the famous lecture given by physicist Richard Feynman (1959), served as the guiding principle for our material exploration. Self-assembling nanostructured materials hold great potential for a variety of applications, for example batteries or water filtration. Self-assembly is a cost-effective way of generating nanostructures on a large scale, that otherwise could not be realized or would not be viable, i.e. in an architectural scale.

Biomimicry of Iridescence

The iridescent façade was inspired by the structural color found on animals, such as birds, beetles, butterflies, fish, etc. These organisms employ bottom-up, structure-directed growth processes to create nano- and micro-structured materials for color creation. Unlike pigments, where color is created by the selective absorbance of light, structural color is the result of the selective reflectance of light on these structures.

Here, we mimicked naturally grown nanostructures by employing a custom-made A, B diblock-copolymer with the ability to self-assemble into a lamella nanostructure.

The iridescent façade was inspired by the structural color found on animals, such as birds, beetles, butterflies, fish, etc. These organisms employ bottom-up, structure-directed growth processes to create nano- and micro-structured materials for color creation. Unlike pigments, where color is created by the selective absorbance of light, structural color is the result of the selective reflectance of light on these structures.

Here, we mimicked naturally grown nanostructures by employing a custom-made A, B diblock-copolymer with the ability to self-assemble into a lamella nanostructure.

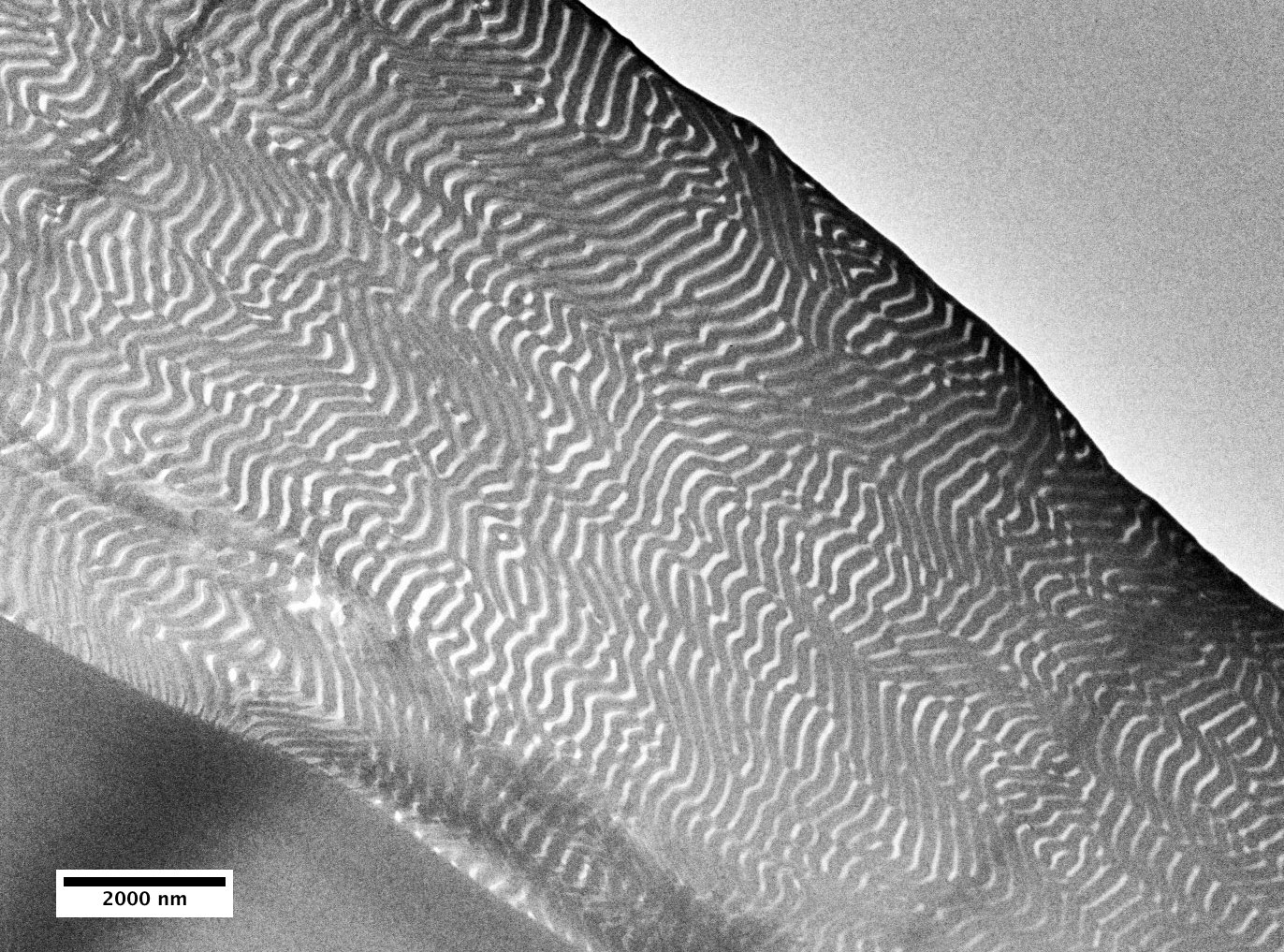

Surface of pavilion under as observed in a transmission electron microscope. A lamella nanostructure is visible that is responsible for the colorful, iridescent appearance.

Pavilion Design

The round needle shape of the pavilion embraces the angle-dependent color apperance of the surface.

Core project team discussing further steps.

Core project team discussing further steps. A Needle Woman on Cornell Campus serving as a site for scientific education about nanotechnology and art.

A Needle Woman on Cornell Campus serving as a site for scientific education about nanotechnology and art.

MAKING and MATERIAL CHARACTERIZATION

Material Synthesis

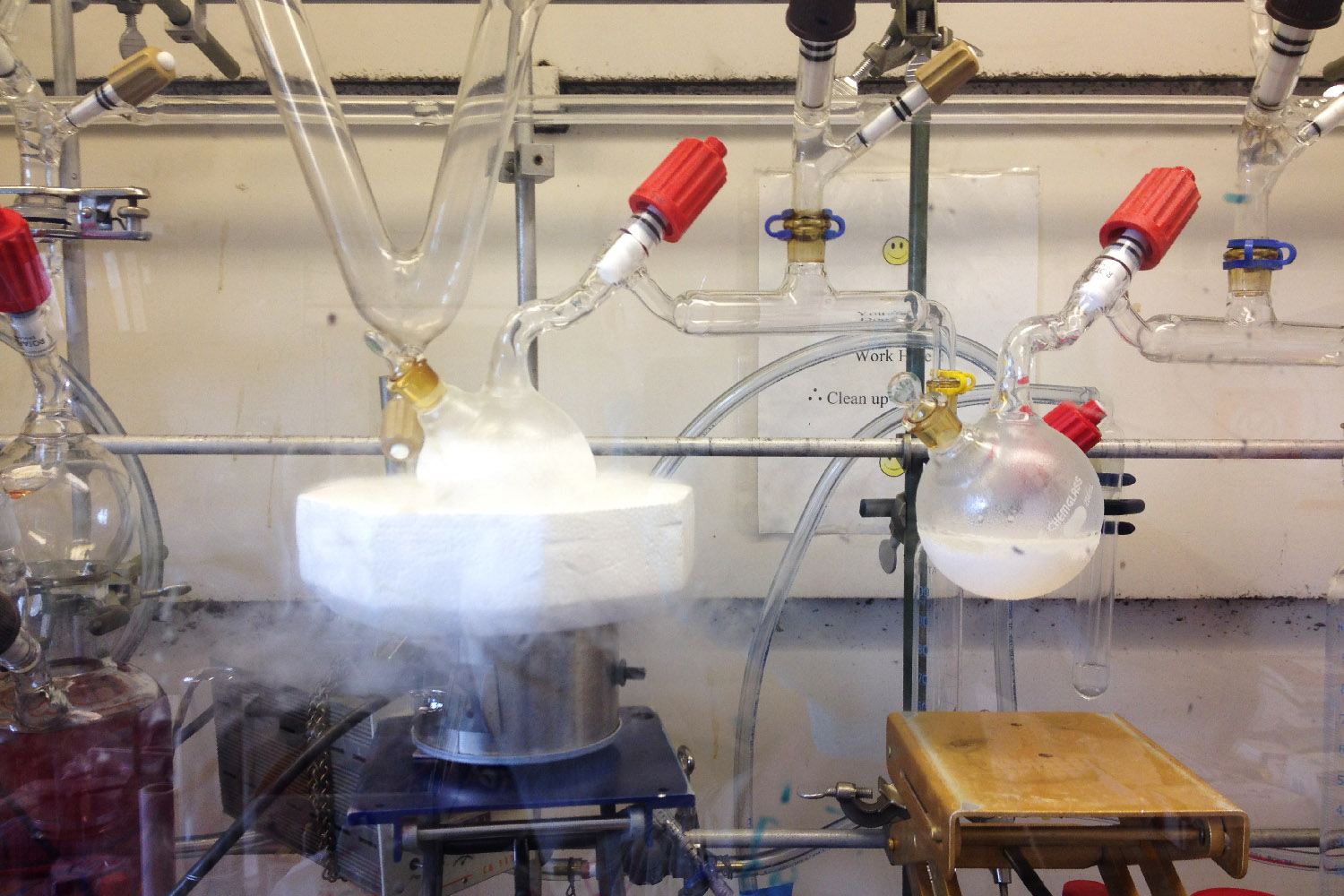

An A, B diblock-copolymer was synthesized using a large-scale, anionic polymerization.

An A, B diblock-copolymer was synthesized using a large-scale, anionic polymerization.

Polymer after synthesis. The molecules are randomly oriented, no nanostructure is presence, hence light is randomly scattered and the material appears white.

Polymer after synthesis. The molecules are randomly oriented, no nanostructure is presence, hence light is randomly scattered and the material appears white.

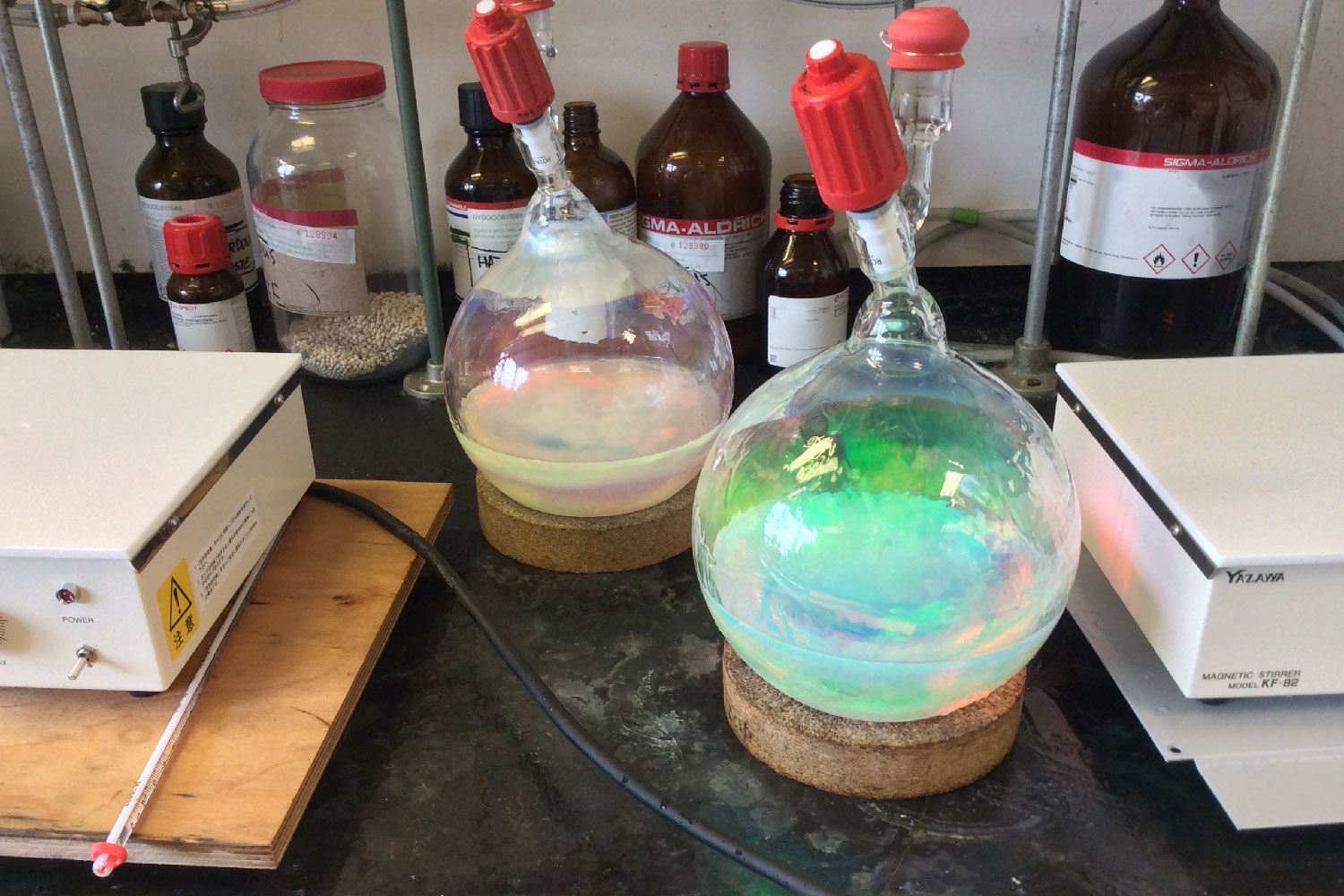

Development of Iridescent Coating

We developed a polymer solution casting process that would allow for us to tune the optical properties of the polymer films. Hundreds of samples were generated to find the optimal conditions for the desired color design.

We developed a polymer solution casting process that would allow for us to tune the optical properties of the polymer films. Hundreds of samples were generated to find the optimal conditions for the desired color design.

Material Characterization

To understand the relationship between molecular mass of the polymer and optical properties, we characterized the polymer films using electron microscopy, X-ray scattering, and optical diffraction measurements.

To understand the relationship between molecular mass of the polymer and optical properties, we characterized the polymer films using electron microscopy, X-ray scattering, and optical diffraction measurements.

Transmission electron microscope.

Transmission electron microscope.

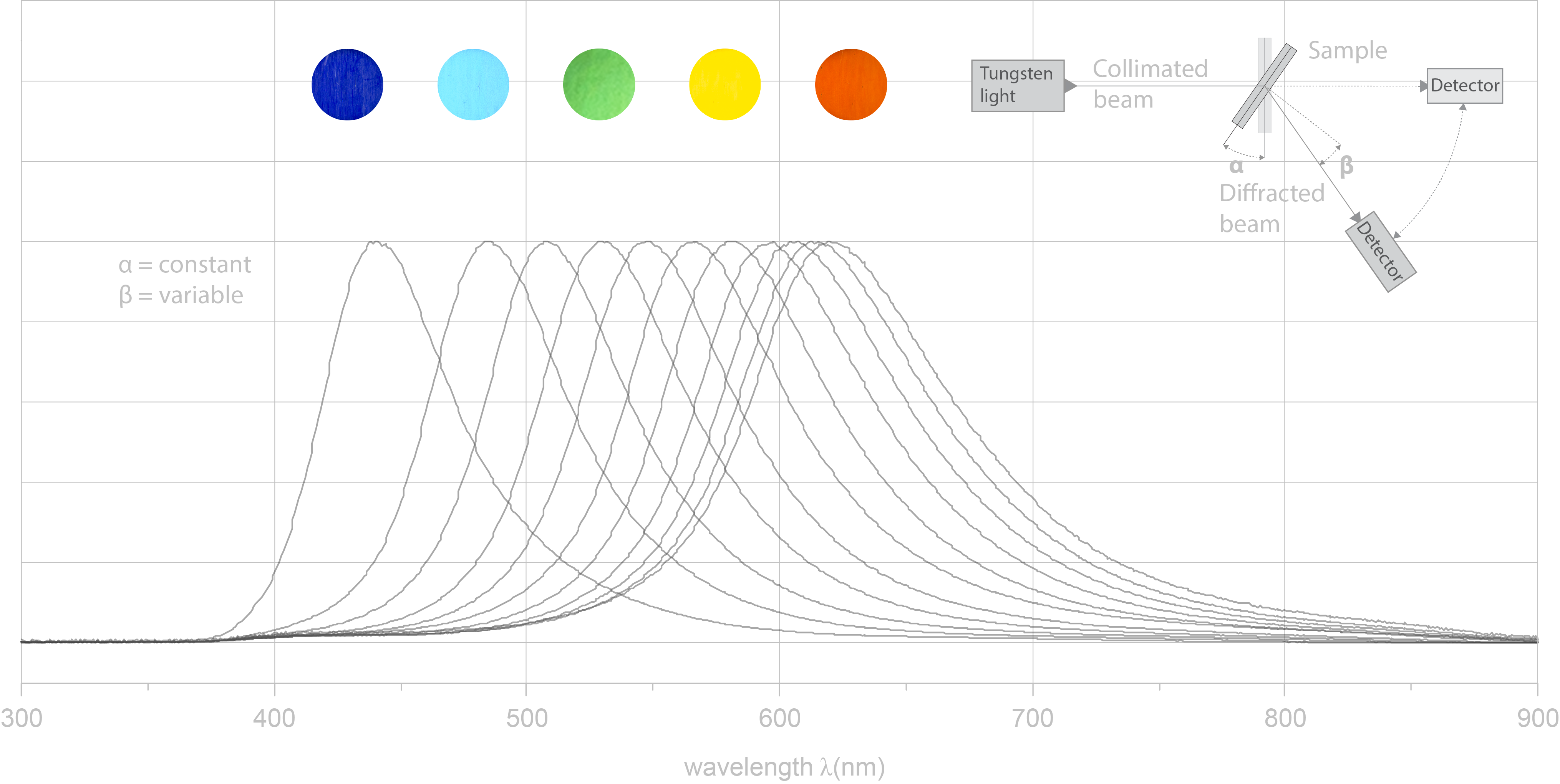

To gain further insight into the polymer nanostructures of the self-assembled optical films, I built a custom tunable spectrograph to determine the d-spacing of the lamella nanostructures.

To gain further insight into the polymer nanostructures of the self-assembled optical films, I built a custom tunable spectrograph to determine the d-spacing of the lamella nanostructures.

Sample data set obrained with the tunable spectrograph above.

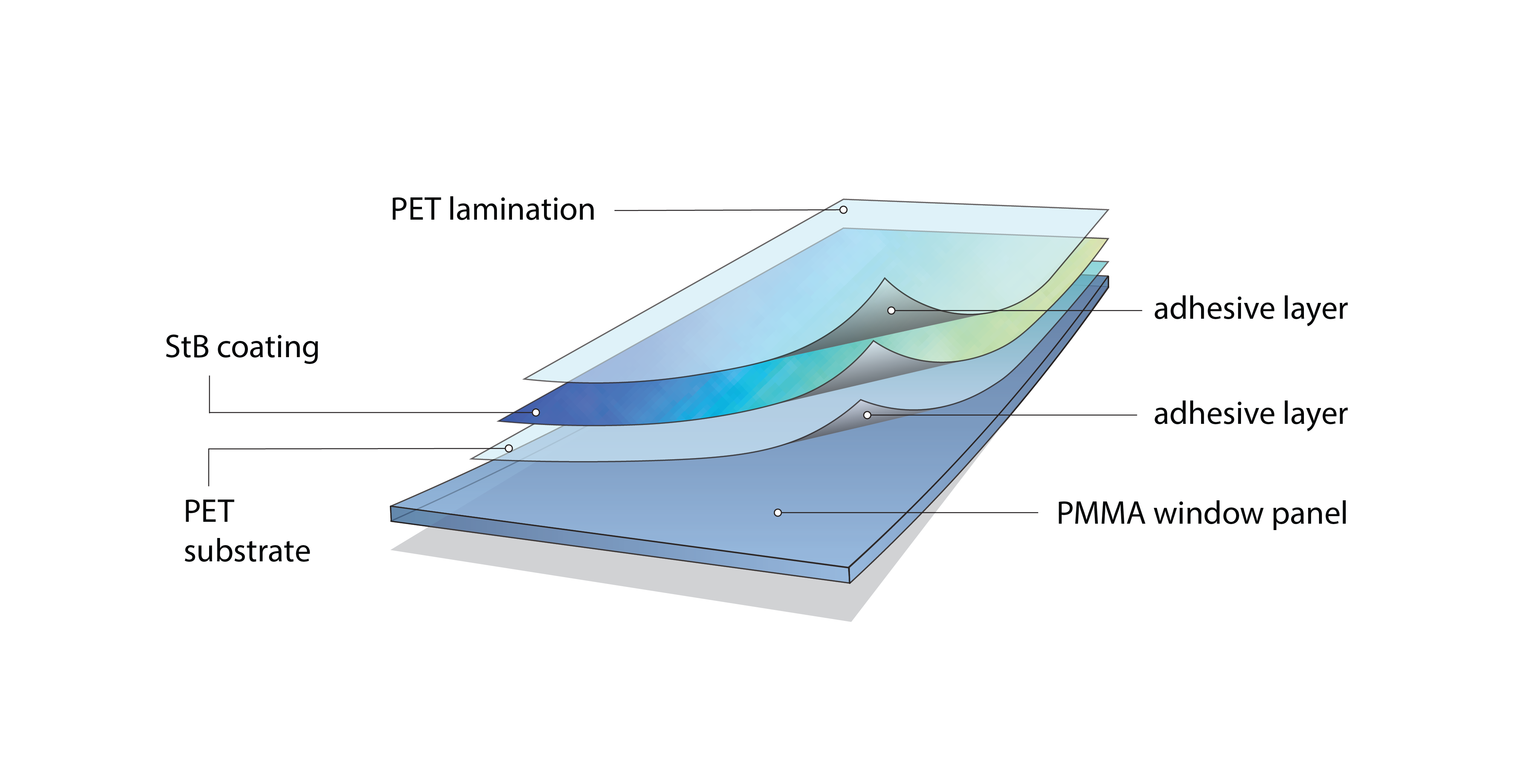

Scaling-up Film Sizes

Scaling up iridescent film size and increasing material synthesis from a lab scale (cm2, g) to an architectural scale (m2, kg) is challenging, as additional factors (mixing of reactants, contaminations issues, safety regulations, production facilities and staff, costs, etc.) need to be considered.

Through rigorous experimentation and with the help of the Cornell University administration as well as passionate volunteers* we overcame these challanges. All final window panels were hand-made using a self-developed casting-lamination process that closely resembles a screen printing process.

*Credits for Panel Production: Troy Batugal, Camila S. Brey Gil, Zhe Chen, Andrew Moorman, Max Vanatta, and many more.

Scaling up iridescent film size and increasing material synthesis from a lab scale (cm2, g) to an architectural scale (m2, kg) is challenging, as additional factors (mixing of reactants, contaminations issues, safety regulations, production facilities and staff, costs, etc.) need to be considered.

Through rigorous experimentation and with the help of the Cornell University administration as well as passionate volunteers* we overcame these challanges. All final window panels were hand-made using a self-developed casting-lamination process that closely resembles a screen printing process.

*Credits for Panel Production: Troy Batugal, Camila S. Brey Gil, Zhe Chen, Andrew Moorman, Max Vanatta, and many more.

Casting of iridescent films.

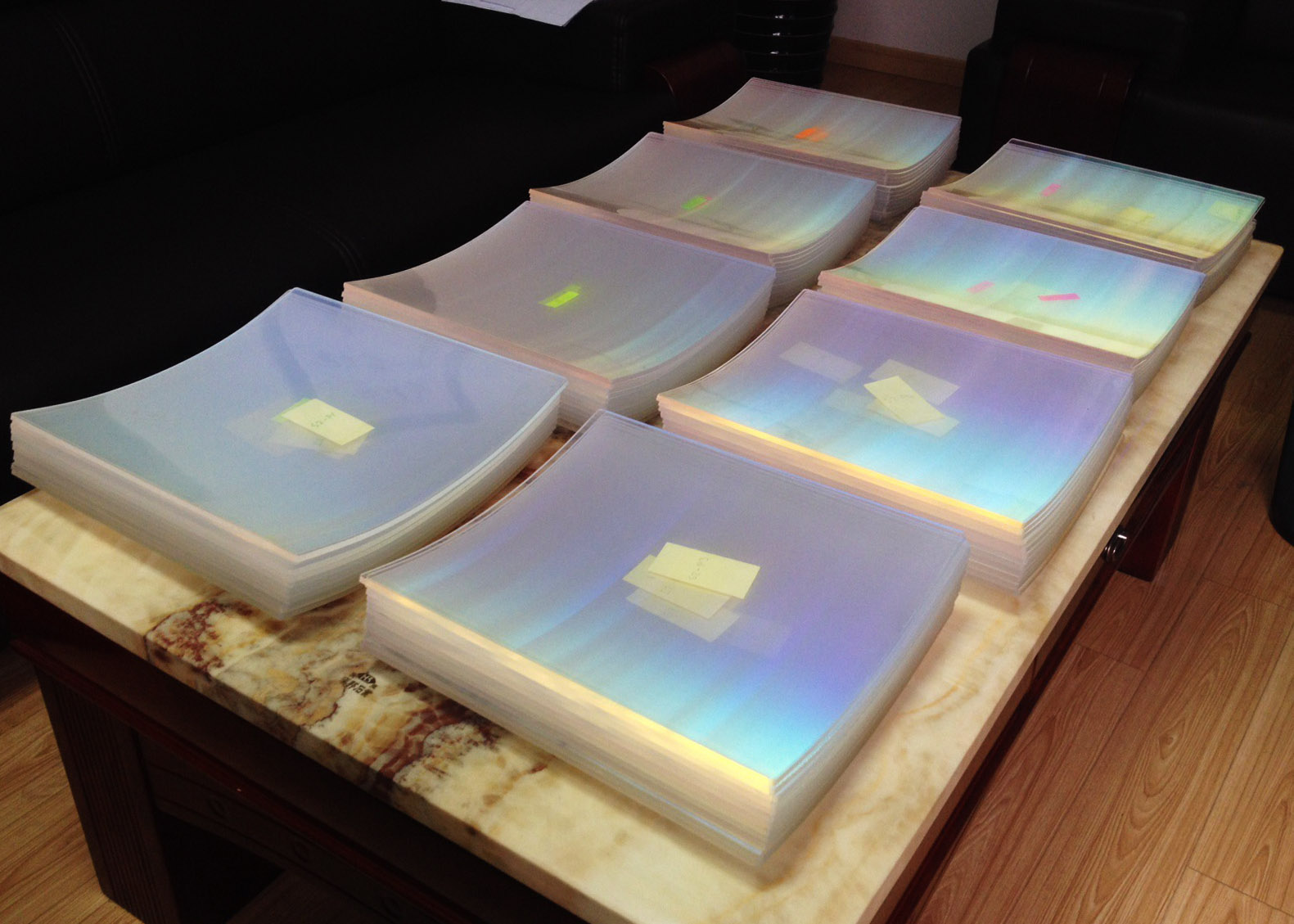

Casting of iridescent films. Final window panels before installation.

Final window panels before installation.

Pavilion Assembly

The pavilion was assembled from steel and aluminum by a Manufacturing group in Mulan, China, and under the suervision of Jaeho Chong.

The pavilion was assembled from steel and aluminum by a Manufacturing group in Mulan, China, and under the suervision of Jaeho Chong.