Deriving Ceramic Tile Designs From Materials Science

Title

QuasiLink

Duration

5 months

Team

Daniel Tompkin, Jenny Sabin (supervision)

Role

Design

Skills

3D printing, Rhino/Grasshopper, CNC milling, Ceramics

QuasiLink

Duration

5 months

Team

Daniel Tompkin, Jenny Sabin (supervision)

Role

Design

Skills

3D printing, Rhino/Grasshopper, CNC milling, Ceramics

QuasiLink is a vertical ceramic screen system with aperiodic symmetry that was inspired by quasicrystals. Quasicrystals are patterns that are able to fill space, but unlike crystals do not possess translational symmetry.

CONTEXT

Despite being so ubiquiteous in their application ceramic tiles and blocks have surprisingly lacked recognition as a viable building component in contemporay architecture practice. The use of CAD/CAM technologies to automate the design and fabrication of ceramic form has inspired a new appreciation for ceramic material in our built environments. QuasiLink serves as a design research project to explore the plastic nature of clay in combination with generative design methods.

DESIGN DEVELOPMENT

The final tiling system was developed in three steps ...

Step I - 2D Tiling System

First, the 2D tile was derived from Tübingen triangles that can be used to model quasicrystals.

The 2D tile is able to fill an area (bottom left), but can also create versatile apertures (bottom right).

First, the 2D tile was derived from Tübingen triangles that can be used to model quasicrystals.

The 2D tile is able to fill an area (bottom left), but can also create versatile apertures (bottom right).

Step II - 3D Base Tile

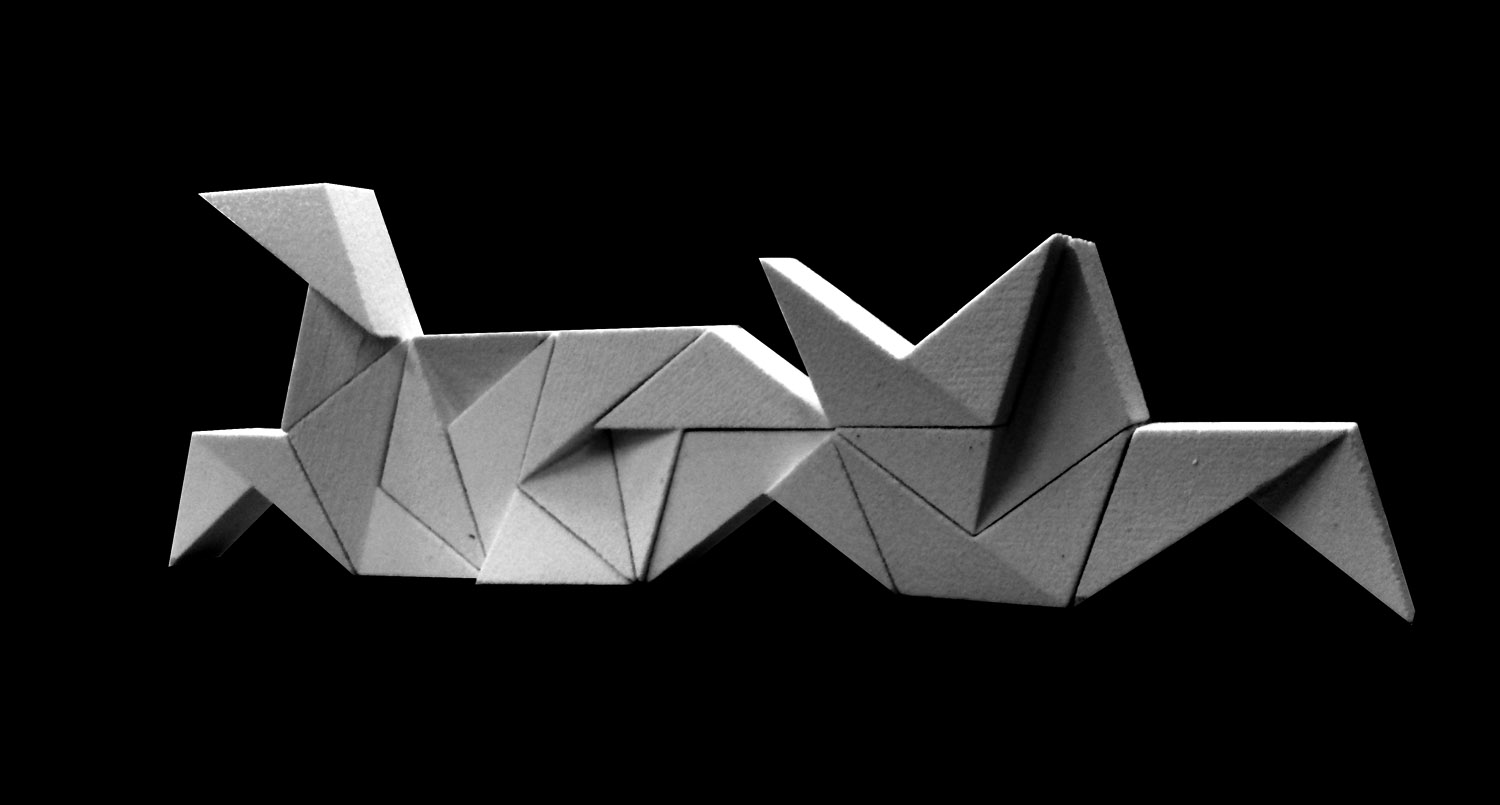

The 2D base tile was turned into a 3D base tile by extrusion into the z-dimension. The 3D base tiles were used as 3D-printed models to explore different aggregation designs.

The 2D base tile was turned into a 3D base tile by extrusion into the z-dimension. The 3D base tiles were used as 3D-printed models to explore different aggregation designs.

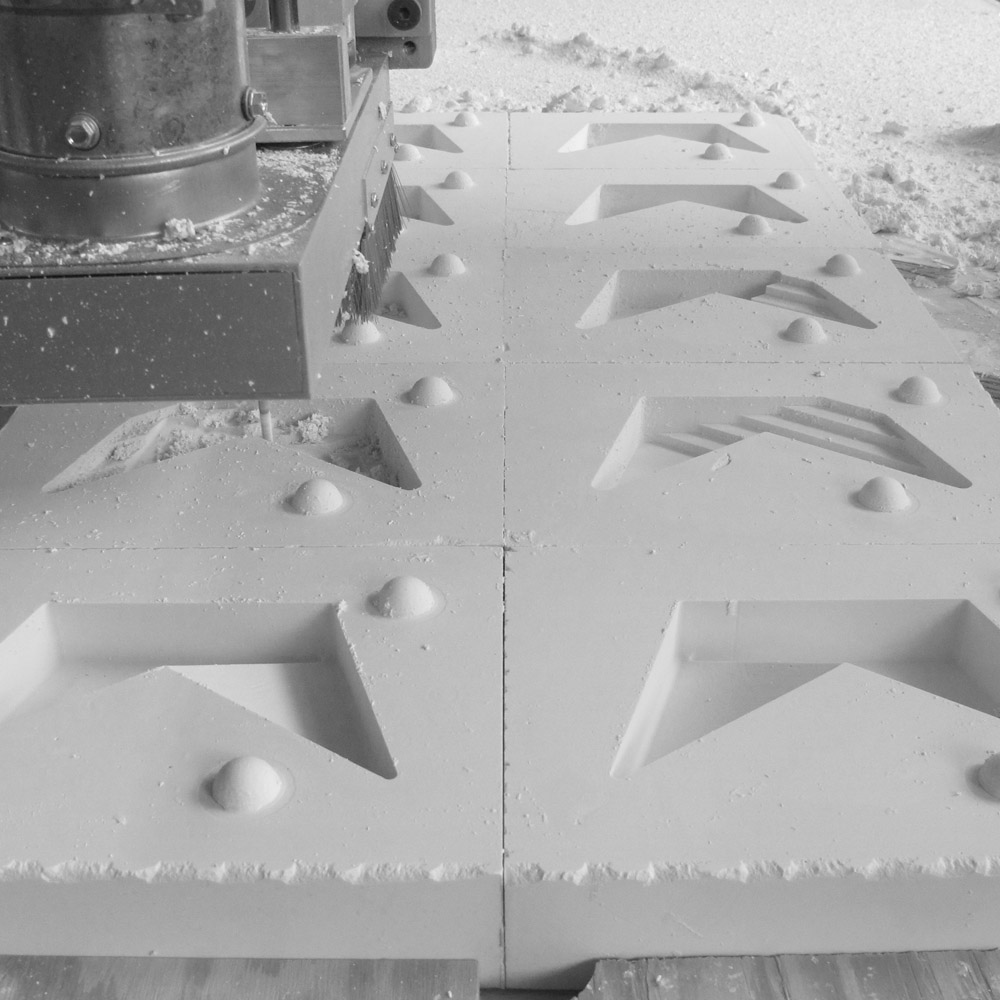

Step III - 3D Tile Ex-/Intrusions

The 3D base tile is further transformed by a series of simple geometric extrusions and intrusions at single points of a tile. This leads to a multitude of different tile designs and results in complex screen designs.

The simple transformations reference the original Tübingen triangles on the final screen.

The 3D base tile is further transformed by a series of simple geometric extrusions and intrusions at single points of a tile. This leads to a multitude of different tile designs and results in complex screen designs.

The simple transformations reference the original Tübingen triangles on the final screen.

MAKING

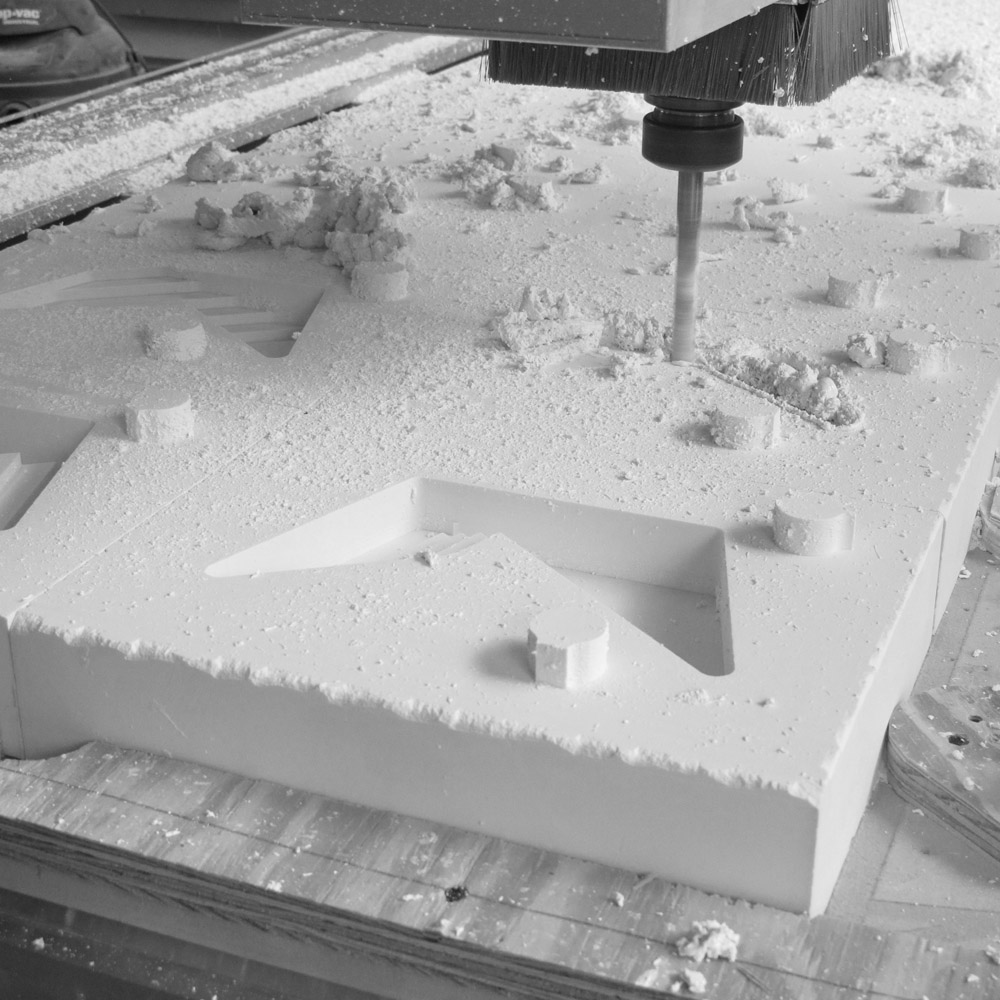

Computer Numerical Control (CNC) Milling

Molds were designed in Rhino 3D and made by CNC milling plaster blocks. All half molds could be combined interchangeably to create a large variety of tile designs.

Molds were designed in Rhino 3D and made by CNC milling plaster blocks. All half molds could be combined interchangeably to create a large variety of tile designs.

Slip-Casting

Liquid slip was poured into the plaster molds and left to densify at the plaster inner surface. Excess slip was drained and reused.

Liquid slip was poured into the plaster molds and left to densify at the plaster inner surface. Excess slip was drained and reused.

Firing

Green ceramic tiles (leather-like consistency) were fired in a kiln to produce a vitrified tile.

Green ceramic tiles (leather-like consistency) were fired in a kiln to produce a vitrified tile.

Glazing

The hardened tiles were glazed with a paint spray gun and fired again.

The hardened tiles were glazed with a paint spray gun and fired again.